Izitimela zesitimela kanye nobuchwepheshe bomhlangano

Ngesidingo sokuthuthuka ngokushesha kwemboni yezitimela, isitimela sikagesi senze inqubekelaphambili enkulu.Njengokupholisa kwezingxenye zokushisisa zesitimela sikagesi we-cooler, kokubili kusukela esakhiweni nasekusebenzeni kwentuthuko esheshayo futhi kubeka phambili izidingo eziphezulu.

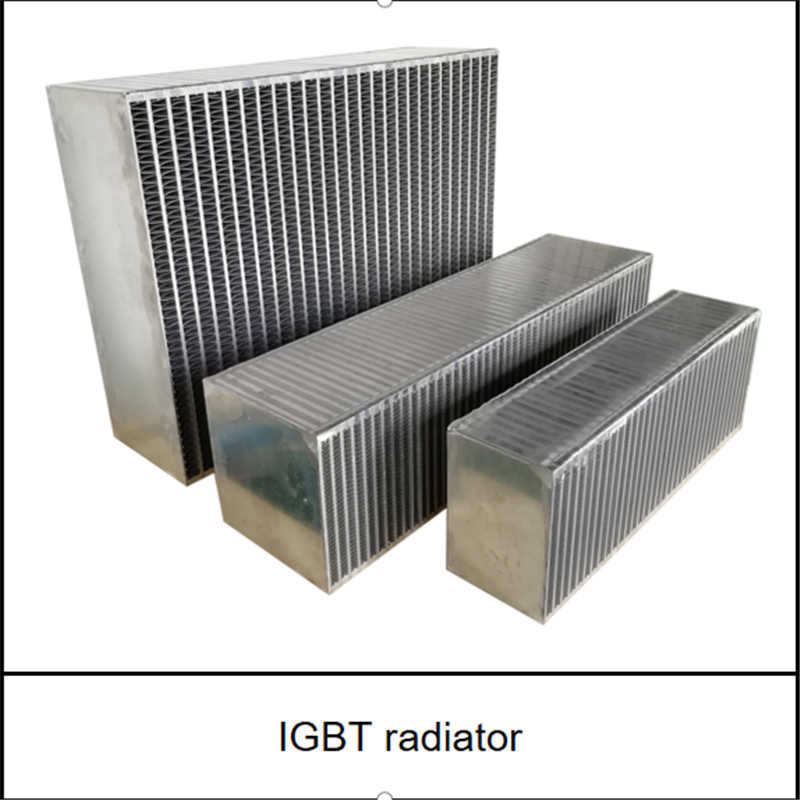

I-Soradiator iklame futhi yathuthukisa ama-radiator e-aluminium anesakhiwo esihlangene, ukusebenza okuhle kakhulu nokuthembeka okuphezulu ukuhlangabezana nesidingo semakethe.I-Soradiator yaklanywa inale ngozi engaba khona engqondweni.Okufana nokudlidliza, ukugqwala kanye nokuvala uthuli okuholela ekwehliseni ukusebenza kahle kokudlulisa ukushisa.Ngasikhathi sinye, ngokwezibalo ezihambisanayo zejika lesici sabalandeli salo lonke uhlelo lokupholisa kanye nejika lesici sokumelana noketshezi lwe-cooler, ukusebenza kwesistimu yokukhipha umoya kanye nohlelo lukawoyela namanzi lwenziwa kahle ngaphansi kwesisekelo sokuqinisekisa ukuthi umthamo wokupholisa we-cooler.

Ukuze kuhlangatshezwane nosayizi oyinhloko kanye nezidingo zokunemba, i-Soradiator iklame, yathuthukisa, yakha futhi yafaka ekukhiqizeni umshini wokuhlanganisa owumgogodla wepuleti-fin onembe kakhulu.Lo mshini wokuhlanganisa oyinhloko ufake isicelo futhi waphumelela isitifiketi sikazwelonke selungelo lobunikazi.Umshini wokuhlanganisa uqinisekisa kakhulu ukuhleleka kwezindiza ezinhlanu zomgogodla, i-perpendicularity kanye nokufana phakathi kwezindiza eziyisithupha.Uma kuqhathaniswa nabanye abakhiqizi, umshini wokuhlanganisa ungaqinisekisa kuphela ukugcwala kobuso obubili noma obuthathu.Inqubo yokuhlanganisa ye-Soradiator iphambili kakhulu kunamazinga embonini.Ngemuva kokuthi umhlangano owumongo usuqediwe, ungapakishwa ngesikhathi esisodwa.Asikho isidingo sokushaya ngesikhathi sokuhlinzwa kwepulasitiki.

Ukuklama nokuthuthukiswa kwe-spring fixture ye-Soradiator, ukulungiswa kwentwasahlobo ngokusebenzisa isitifiketi sikazwelonke selungelo lobunikazi, yonke imininingwane encane iwukuqinisekisa usayizi, i-perpendicularity, flatness, parallelism kanye nokubukeka komnyombo.Ngesikhathi esifanayo, amandla e-brazing of core ayathuthukiswa.