ama-coolers kawoyela we-hydraulic

Ama-cooler kawoyela weHydraulic angamathuluzi asetshenziselwa ukulawula izinga lokushisa loketshezi olunamanzi kumasistimu asebenza ngogesi.Zisiza ukugcina izinga lokushisa elilungile lokusebenza ngokukhipha ukushisa okukhiqizwa phakathi nokusebenza kwesistimu.Izipholile zikawoyela weHydraulic ngokuvamile zihlanganisa uchungechunge lwamashubhu noma amaphiko akhulisa indawo engaphezulu yokudlulisa ukushisa.Njengoba uketshezi olushisayo lwe-hydraulic lugeleza endaweni epholile, lushintshanisa ukushisa nomoya ozungezile noma indawo yokupholisa ehlukile, njengamanzi noma olunye uketshezi.Le nqubo ipholisa uketshezi olunamanzi ngaphambi kokuthi lubuyele ohlelweni, luvimbele ukushisa ngokweqile nokuqinisekisa ukusebenza kahle kwesistimu.

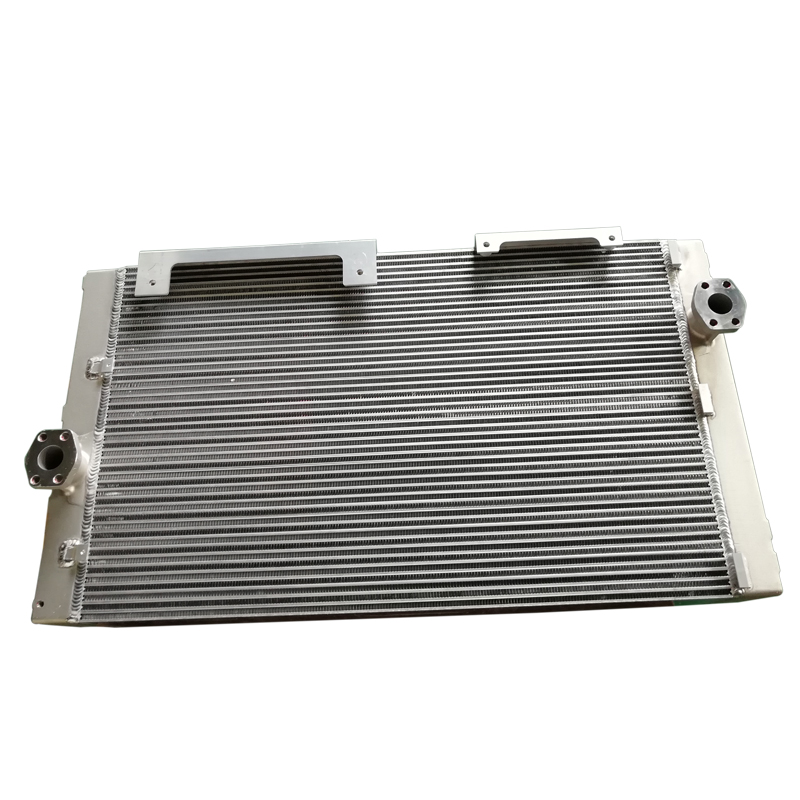

Thatha uhlelo lwe-hydraulic njengesibonelo, imishini idinga ukugcina ukucindezela okuphezulu ngokuqhubekayo lapho isebenza, okuzokhiqiza ukushisa okukhulu, futhi izinga lokushisa likawoyela lizokhuphuka ngemva kwesikhathi eside somsebenzi.Uma ukushisa kungakhululwa ngesikhathi, kuzoholela ekugugeni nasekulimaleni kwezakhi zokuvalwa kwesistimu, futhi i-viscosity yamafutha iba ngaphansi ngokukhuphuka kwezinga lokushisa likawoyela, futhi ingcindezi kawoyela ayikwazi ukuhlangabezana nezidingo. lomsebenzi.Ukuqinisekisa ukusebenza okuphephile nokuthembekile kwemishini.Izinga lokushisa likawoyela kufanele lilawulwe ngaphakathi kwebanga elinqunyiwe.Isizathu esiyinhloko sokukhuphuka kwamafutha okushisa kwesistimu yokugcoba ihlukile kunesistimu ye-hydraulic, kodwa kuyadingeka futhi ukulawula izinga lokushisa lamafutha lamafutha okugcoba ebangeni elinqunyiwe.Futhi ingxenye ethwala lo mthwalo wemfanelo i-oil cooler.I-oil cooler isetshenziselwa ikakhulukazi ukupholisa uwoyela we-hydraulic namafutha okugcoba;I-oil cooler isetshenziswa kakhulu emishinini yepulasitiki, imishini yobunjiniyela, imishini yezimayini, imoto, insimbi, amandla omoya, i-aerospace nezinye izimboni.Kunezinhlobo eziningi zokupholisa uwoyela, ezingahlukaniswa zibe uhlobo lweshubhu kanye nohlobo lwephiko lepuleti.Uma kuqhathaniswa nesibandisi sikawoyela sohlobo lwe-tubular, isipholile sikawoyela sohlobo lwe-plate-fin singamelana nokucindezela okuphezulu ngenxa yezici zaso zesakhiwo.Lokhu kwenza i-cooler yohlobo lwe-plate-fin isetshenziswe kakhulu ekukhiqizeni amandla omoya, uhlelo lwe-hydraulic, isitimela sesitimela nezinye izinkambu.

I-Soradiator igxile kakhulu ekuthuthukisweni nasekuthuthukisweni kwe-cooler ye-plate fin yohlobo lwamafutha.Ngemuva kweminyaka engaphezu kweshumi yokuhlola nokuthuthukiswa, kwakheka umugqa wokukhiqiza oqinile, osebenza kahle, ophezulu, wekhwalithi ephezulu, oguquguqukayo we-fin fin radiator.Onjiniyela bahlala bethuthukisa futhi bephelelisa inqubo yokukhiqiza.Kusukela ekucabaneni kwe-partition, isakhiwo se-fin, izindinganiso zokuhlanza, inqubo yokuhlanganisa, ubuchwepheshe be-vacuum welding kanye nokulawula isikhathi, ukuhlolwa kokuqina komoya, ukushisela ipulaki, kuye kwakha isethi yezindinganiso zokukhiqiza ezithuthuke kakhulu nezesayensi.Izinga lokuphasa ngesikhathi esisodwa se-plate-fin core lifinyelela ngaphezu kwama-99%.Ngasikhathi sinye, abakhiqizi be-Soradiator bangakwazi ukulungisa ukwakheka kwe-fin, usayizi we-fin kanye nokumelana nokucindezela kwe-radiator ngokuya ngezidingo zemishini kanye nemingcele enikezwe amakhasimende, ukuze kukhiqizwe imikhiqizo efaneleke kakhulu kumakhasimende ukuhlangabezana nazo zonke izidingo. yamakhasimende e-radiator yohlobo lwe-fin kanye ne-oil cooler.